Founded in 2003, JIAXING TAITE RUBBER CO., LTD is a Sino-German joint venture specialized in rubber tracks and rubber pads manufacture. Drawing from the decades of R&D experience of our German partner, and by the endeavor of our technical staff, Taite now possesses strong technical resource and several patents in rubber track industry. This enables our products to precede others' in both diversity and quality.

Since its establishment, Taite strives to build a modern enterprise with high efficiency. Our company has built a laboratory with comprehensive equipments, as well as several workshops with advanced manufacturing facilities. Taite is qualified with ISO9001-2015 quality management system. Besides, we have also imported IATF16949 to guide our process control. In the workshop, Taite runs complete 6S management and lean production to ensure stable and high level quality of our products. In this way, Taite realizes an effective system to prevent failure and flaw during manufacturing, and reduces the deviation in supply chain. Moreover, these effort we have done enable us the ability to produce customized products for our clients.

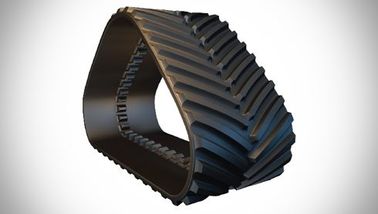

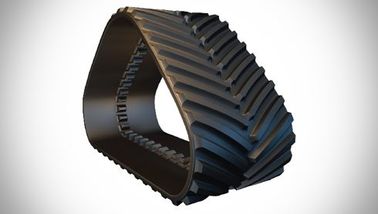

We produce a variety of rubber tracks and rubber pads that can be widely applied in construction machinery, agricultural machinery and other specialized vehicles. Most of our products are sold to Europe, America, Australia etc. In more than 10 years development, Taite has established long-term and stable cooperative relationship with some famous OEM customers, and widely won recognition and praise from them.

In the future, we will continue to concern from the perceptive of our customers, and constantly strive for perfection in all aspects: technology research, product quality, service and cost performance.

Welcome domestic and oversea customers come to our company for cooperation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!